Sublimation Engraving & Printing

In the ever-evolving world of recognition and achievement, the trophy and awards industry has undergone a dramatic transformation thanks to modern technology. One of the most significant innovations fueling this change is sublimation printing. This advanced method allows awards professionals to create vibrant, long-lasting, and highly customized recognition products faster and more efficiently than ever before.

Whether you’re an award retailer, a shop owner, or an engraver looking to expand your offerings, sublimation printing opens the door to a wide range of creative possibilities—from full-color plaques and nameplates to detailed medallions and custom corporate awards.

In this article, we’ll explore everything you need to know about sublimation printing in the context of the trophy and awards industry, including how it works, the materials involved, its key benefits, and why it’s rapidly becoming the standard for personalized recognition.

What is Sublimation Engraving?

Sublimation engraving is a heat transfer printing technique that uses heat and pressure to transfer dye onto specially coated surfaces. The ink used in this process transforms directly from a solid into a gas (a process known as sublimation) without becoming a liquid. This allows the dye to penetrate the surface of the material, rather than just sitting on top.

In the awards and recognition industry, this translates to permanently embedded graphics, vibrant colors, and photo-quality finishes on a variety of substrates, including metal plaques, acrylics, nameplates, and more.

Sublimation Printing & the Awards Industry

The sublimation process involves three main steps:

Step 1: Designing the Artwork

Using design software like CorelDRAW, Adobe Illustrator, or proprietary trophy design programs, a graphic is created to match the dimensions of the product. Common elements include logos, recipient names, event details, dates, and even photos.

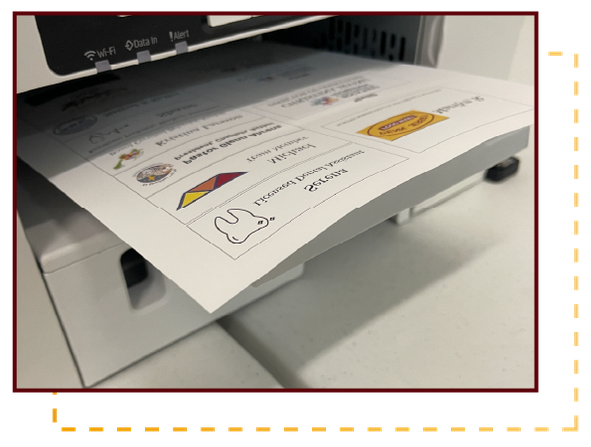

Step 2: Printing the Transfer

The artwork is mirrored and printed onto sublimation transfer paper using a printer loaded with sublimation ink.

Step 3: Heat Press Transfer

The printed design is aligned with the blank award substrate (usually a coated metal or polymer). A heat press applies high heat (around 400°F) and pressure for a set time, typically 30–60 seconds.

The ink becomes a gas, penetrates the surface coating, and solidifies, creating a durable, high-resolution image.

What Awards are sublimated?

We have been using sublimation technology for nearly 15 years now and can adapt it to work for most awards and recognition items. Here are a few of our most popular sublimated items!

Our custom medals are made using a sublimated disc that attaches to the inside of a solid cast medal. This allows us to be able to make one single medal without making molds typically done with die casting. The graphics are vibrant and clear and perfect for any event.

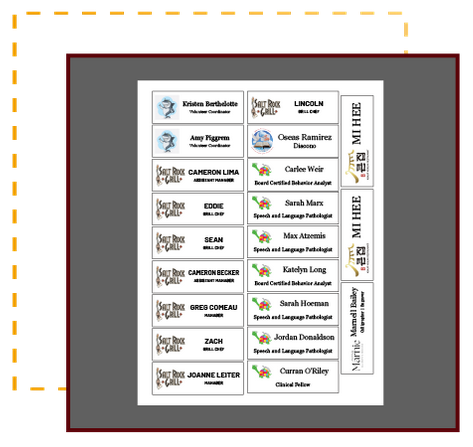

Sublimation engraving has completely changed the game for our name tag customers. Not only can you know put your logo in full color on your tags, but the engraving lasts longer since the ink is pressed into the metal. Unlike silk-screening or UV printing, the sublimated images will never scratch off or fade over time making these one of the most durable name tags on the market.

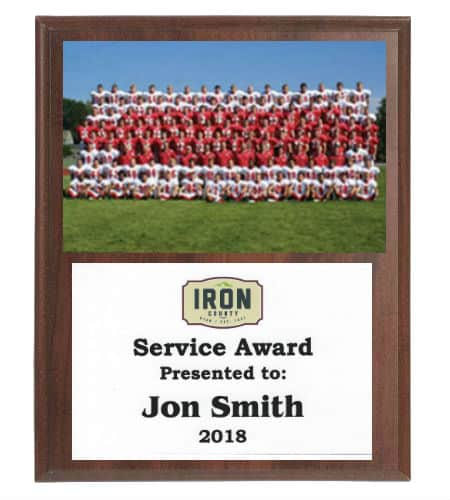

This iconic piece of recognition was brought back to life with sublimation. Adding full color logos to corporate plaques ensured cohesive branding and coaches and schools loved adding team photos to remember their seasons. The possibilites for awards plaques has become endless!

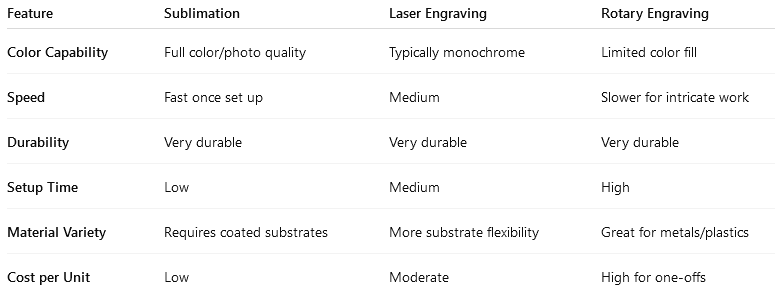

Comparing Sublimation to Traditional Engraving and Laser Etching

5 Tips When Sublimating

1. Use High-Resolution Images

Start with images at 300 DPI or higher to ensure sharp, detailed prints.

2. Pre-Press When Necessary

Remove moisture and wrinkles from substrates like fabric or wood panels before applying the transfer.

3. Prevent Ghosting

Use heat-resistant tape to hold the transfer paper in place. Avoid shifting the paper after pressing.

4. Calibrate Color Management

Colors may print differently on sublimation substrates. Use ICC profiles and conduct test prints for accurate output.

5. Keep Substrates Clean

Dust or fingerprints can cause discoloration or imperfections in the final product.

Conclusion: Why Sublimation Printing is the Future of Custom Awards

Sublimation printing is rapidly becoming the preferred method for creating high-quality, fully personalized awards across industries. Its vibrant color output, efficiency, and versatility allow trophy shops and recognition businesses to offer unique, durable, and memorable products with quick turnaround and minimal cost.

If you’re in the trophy and awards industry, adopting sublimation printing isn’t just an upgrade—it’s a competitive advantage. From sports and corporate recognition to school and memorial awards, the ability to create stunning, full-color designs on demand has never been more accessible.