Being in the business of engraving for over 37 years, we understand the ins and outs of diamond engraving very well.

Diamond Engraving, also called “Scratch Engraving” or “Diamond Drag Engraving,” uses a diamond-tipped tool that scratches the surface to create the design.

This method removes material from the surface, revealing an underlying color or leaving a permanent etched mark.

Step 1: Design

Using design software like EngraveLab Expert, a graphic is created to match the dimensions of the product.

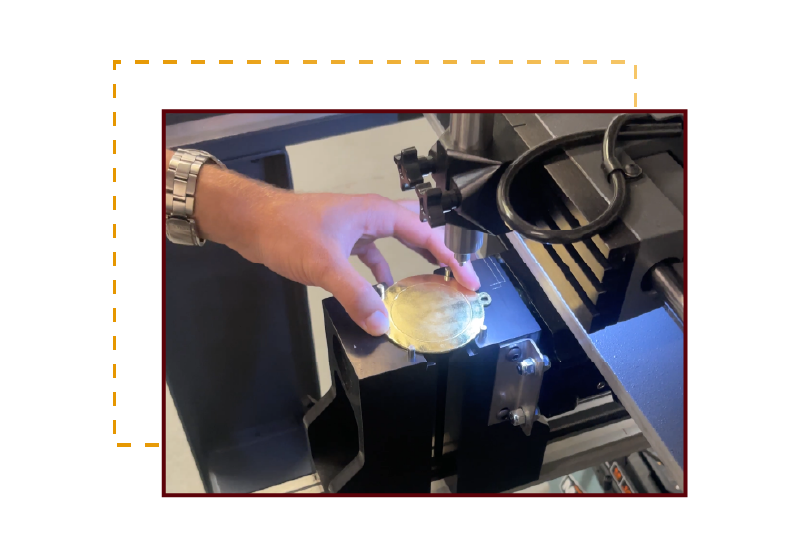

Step 2: Secure and Center

Secure item in the engraver. Measure and set the graver to the middle for a centered design.

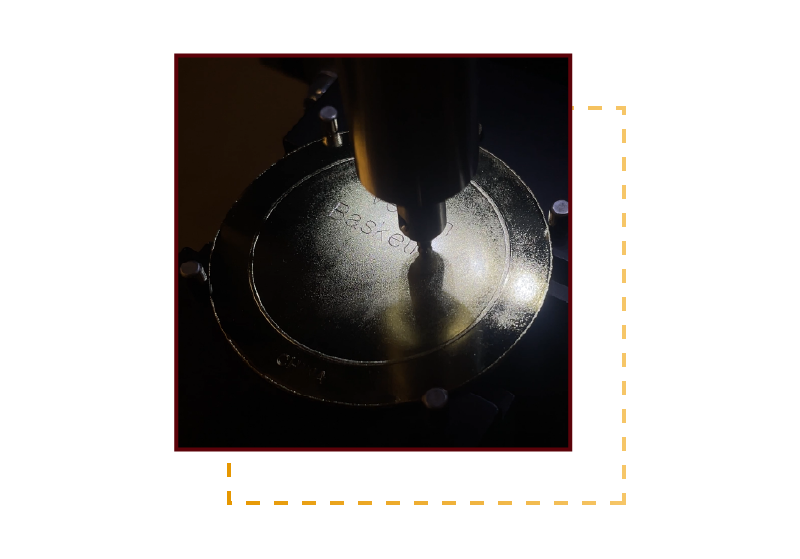

Step 3: Engrave!

Press start on the machine and run program.

The graver then drags across the medal leaving an engraved design!

Engravable Brass Bells

Engraved Uniform Nametags

Diamond Engraving vs Laser Engraving: Which Is Better?

Which is better depends on your goals:

-

Choose diamond engraving if you want clean, elegant, timeless, scratch-resistant engraving on metal, especially for name tags, jewelry, or formal awards.

-

Choose laser engraving if you want bold graphics, flexible materials, or are working with wood, plastic, or high-detail logos.

Listed Below are some of the differences between each engraving type:

| Feature | Diamond Engraving | Laser Engraving |

|---|---|---|

| Engraving Method | Physically etches surface with a diamond-tipped stylus also known as a “graver” | Uses a focused laser beam to burn/vaporize the surface |

| Best For | Metals (brass, aluminum, stainless), jewelry, awards | Wood, plastic, coated metals, photos, logos |

| Look | Subtle, classic, timeless and precise scratch with no color | High-contrast, can appear dark or colored depending on material |

| Line Thickness | Thin lines (.003″–.005″), limited by stylus size. Can still acheive bold fills with multi line fonts. | Fully adjustable. Acheives thin lines or bold fills |

| Detail & Logos | Great for text and clean line art | Ideal for highly detailed graphics and photo engraving |

| Material Compatibility | Uncoated metals, glass, crystal | Wood, plastic, coated metals, glass, leather, stone |

| Durability | Durable and long lasting, etches into the material | Also durable but dependent on material or coating |

| Cost | Moderate, especially for deep/detail work | Low–moderate, more scalable for bulk |

| Speed | Moderate—slower for longer text/logos | Fast, great for batches or raster jobs |

| Scratch Resistance | Yes | Depends on surface treatment |

| Best Use Cases | Metal name tags, jewelry, plaques, industrial marking | Wood signs, plastic labels, photo engraving, coated tags |

How Durable Is Diamond Engraving?

Diamond engraving is one of the most durable engraving methods available.

This is especially true when used on metal surfaces like stainless steel, aluminum, or brass.

Unlike surface-level printing or etching that sits on top of the material, diamond engraving physically cuts into the surface using a sharp, diamond tip.

This means the marking is permanent, scratch-resistant, and is generally unaffected by wear and tear.

Durability benefits:

- Fade-proof: no ink or surface coating to wear away.

-

Weather-resistant: On metals like stainless steel or aluminum, it stands up to heat, moisture, and sunlight.

-

Long-lasting: Perfect option for heirloom pieces, industrial tags, plaques, and items that are meant to last for years.

Customization Options and Design Tips

One of the biggest benefits of diamond engraving is that it offers clean, professional customization on metal items like name tags, plaques, and gifts.

It still delivers a timeless, classic, and elegant look when properly designed.

What Can Be Customized with Diamond Engraving?

-

Text: Names, titles, dates, serial numbers, and short messages

-

Logos: Simple, line-based logos or vector artwork (no shading or color)

-

Fonts: A variety of fonts can be used, but thin-line or single-line fonts work best

-

Layout: Centered, left-aligned, or multi-line formatting options available

Because diamond engraving relies on a fine-tipped stylus, it’s best for clean, legible designs with a high level of precision.

This is why it’s a popular choice for corporate name tags, award plaques, and jewelry inscriptions.

Cost, Turnaround, and Ordering Details

How Much Does Diamond Engraving Cost?

The cost of diamond engraving depends on:

-

Item type and size (e.g., name tag vs. large plaque)

-

Amount of text or design complexity

-

Whether you’re adding a logo or artwork

Overall, diamond engraving is a cost-efficient solution for either individual items or bulk orders.

Custom logos and longer messages may increase the price slightly, depending on setup and time involved.

Turnaround Time

We know your time is important and that speed matters. That’s why we keep our production process fast and efficient.

Average processing time: 1–2 business days

Production times may vary on order quantity.

Rush production is available at checkout.

How to Order

Ordering your custom diamond engraving is easy:

1. Choose your product (e.g., name tags, plaques, or diamond-engraved brass bells).

2. Customize it with your text and/or logo.

3. Submit your order and artwork.

4. We’ll handle the rest with fast shipping!

Use this link to inquire about ordering a custom engraving

We’ve engraved anything from a frying pans to watches!

FAQs About Diamond Engraving:

How Deep Is Diamond Engraving?

Diamond engraving typically creates very shallow marks, ranging from .003” to .005” deep.

While the lines are shallow, they’re sharp and long-lasting due to the precision of the diamond tip.

You can increase depth slightly by repeating the engraving path or increasing pressure, but this can also affect clarity on thinner materials.

Can You Engrave Curved Surfaces with Diamond Engraving?

Yes, but it depends on the curvature and the type of engraving machine.

Many modern engraving setups allow for rotary fixtures or adjustable jigs, which let us engrave on curved items like:

-

Metal cups

-

Cylindrical bells

-

Pens or tubes

However, extremely rounded or uneven surfaces may require a different method, such as laser or hand engraving.

Is Diamond Engraving Safe for Heirlooms or Sentimental Items?

Absolutely. In fact, diamond engraving is often chosen for high-value or irreplaceable items because it’s non-invasive and doesn’t use heat or chemicals.

The stylus gently carves into the surface without distorting, burning, or weakening the item.

We always recommend a test piece when possible, but rest assured — this method is trusted for jewelry, military medals, watches, and other keepsakes.

Can You Color Fill Diamond Engraving?

Yes — and it’s a great way to boost visibility, especially on shiny or high-polish metals.

After engraving, we can apply a blackening agent or enamel into the grooves to create contrast. This is especially helpful on:

-

Brass

-

Stainless steel

-

Gold or silver finishes

Note: Not all items are suited to color-fill, and certain materials may not oxidize. Ask us for recommendations when ordering.

Will My Logo Work with Diamond Engraving?

Most likely — as long as it’s line-based or vector-based. Diamond engraving is best suited for:

-

Thin outlines

-

Text-based logos

-

Simple illustrations

If your logo includes shading, gradients, or photo-style detail, it may need to be converted or simplified first.

We can help convert raster logos (like PNG or JPG) into clean vector files ready for engraving.

Does It Leave Burrs or Sharp Edges?

No — diamond engraving typically leaves a very smooth, clean finish.

Because the stylus scratches rather than cuts deeply, there’s minimal risk of burrs, snags, or raised edges.

On soft metals like aluminum, there may be slight surface texture changes, but we inspect each item before shipping to ensure a clean, polished result.

How Long Does Diamond Engraving Take?

The actual engraving process is usually very fast — just a few minutes per item. But when ordering custom engraving, processing time includes:

-

Artwork setup

-

Machine setup and alignment

-

Finishing and inspection

Our standard turnaround time is 1–2 business days, and we can accommodate rush orders when needed.

How Do I Care for an Engraved Item?

Engraved items require minimal care. We recommend:

-

Wiping with a soft cloth

-

Avoiding abrasive cleaners

-

Applying polish if metal becomes dull

The engraving itself won’t fade or disappear — it’s cut directly into the material and made to last.

Why Choose Diamond Engraving? Final Thoughts:

Diamond engraving stands out as one of the most precise, durable, and professional engraving methods available today.

Whether you’re customizing a metal name tag, a corporate award, or a keepsake gift, it offers a clean, permanent result that won’t fade, chip, or wear off.

While it may not support full-color or shaded graphics like laser engraving, diamond engraving more than makes up for it with elegance, legibility, and long-term durability—especially on metal surfaces.

If you’re looking for a timeless, high-quality finish for your next custom project, diamond engraving is a reliable and trusted choice.

Want to learn more?

- Learn About Sublimation Engraving Here