Laser engraving is one of the most precise and durable methods for customizing and marking a wide variety of materials.

Whether you’re a business owner, product designer, or simply someone looking to personalize a gift, laser engraving offers a clean, permanent, and professional finish.

In this post, we’ll cover how laser engraving works, which materials are best suited for it, design best practices, and common pitfalls to avoid.

We’ll also highlight some specific use cases and share different ideas to help you with your next project.

What Is Laser Engraving?

Laser engraving is the process of using a concentrated beam of light (a laser) to remove material from the surface of an object.

Unlike printing or painting, engraving cuts directly into the surface, creating a lasting mark that won’t fade or peel.

Key benefits include:

- High precision and detail

- Permanent, professional results

- Contactless process (no need for ink or pressure)

- Applicable to a wide range of materials

Common uses:

- Personalized gifts

- Corporate branding

- Product customization

- Signage and awards

How Does Laser Engraving Work?

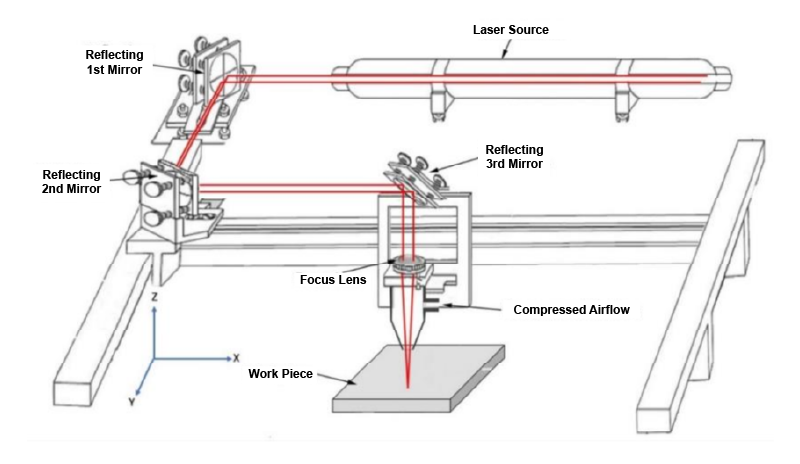

Laser engraving works by directing a high-powered beam of light at a material.

The beam vaporizes or melts away a thin layer of the surface material.

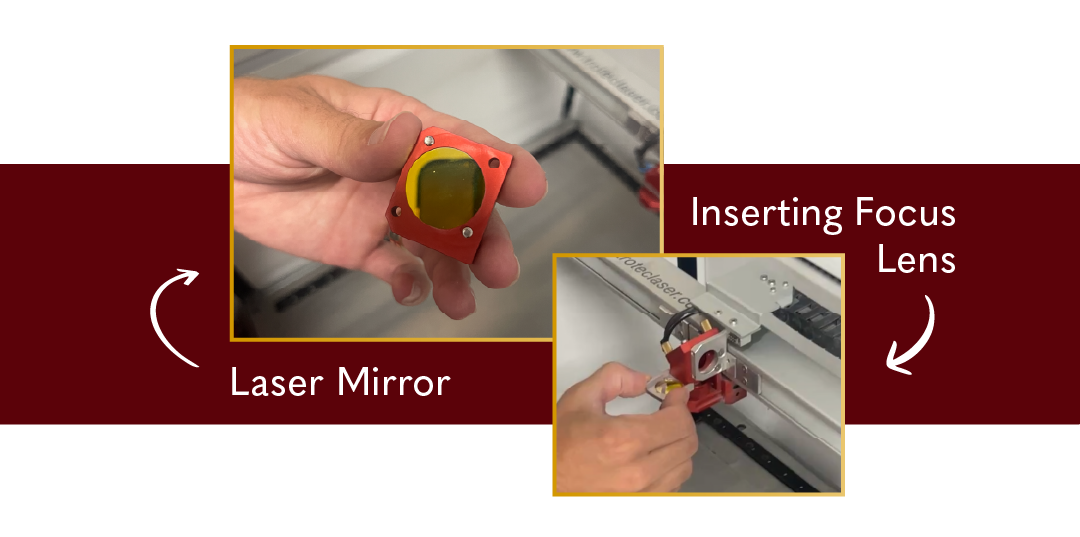

Laser engraving uses a series of mirrors reflecting the light towards the material like in the diagram below.

It then goes through a lens to concentrate the light. (focus Lens)

As the laser moves back and forth it rapidly turns on and off to engrave the product.

Two common engraving modes:

- Raster engraving – The laser moves left-to-right, line by line, like a printer.

- Vector engraving – The laser follows defined paths or outlines, ideal for text and simple shapes.

Laser Engraving Different Materials:

Leather

Not all leather reacts well under a laser. Some look beautiful. Others can release unpleasant or dangerous fumes.

Best options:

- Vegetable-tanned leather – reacts beautifully, deep contrast

- Top/full-grain leather – high-end, consistent results

- Suede & nubuck – soft, rustic texture

Avoid:

- Chrome-tanned leather – may release harmful fumes

- Synthetic (PU or vinyl) – melts and emits toxic gases

- Painted/heavily treated leather – unpredictable results

Pro tip: Always test a small section or check with your supplier.

Glass

Laser Engraving works best on flat glass items like awards, drinkware, mirrors, and ornaments.

Because glass can be brittle, it’s important to use lower power settings and multiple passes to avoid cracking or chipping.

The result is a clean, semi-opaque design that catches the light perfectly. Generally best for both decorative and corporate applications.

Tumblers

Laser engraving is perfect for personalizing tumblers, especially those made from stainless steel or coated with powder finishes.

The process works by precisely removing the outer layer of coating (or subtly marking the bare metal), revealing the underlying surface and creating a high-contrast, permanent design.

Unlike screen printing or vinyl decals, laser engraving won’t fade, scratch off, or deteriorate with washing.

It’s ideal for custom logos, names, graphics, or branding on items like YETI-style cups, water bottles, and travel mugs.

Aluminum

Aluminum is one of the most popular metals for laser engraving thanks to its lightweight, durable properties and clean finish.

It can be engraved in two primary forms: anodized aluminum, which has a colored coating that the laser removes to reveal a bright contrast underneath, and bare aluminum, which requires a fiber laser for deep, high-contrast marking.

Anodized aluminum is especially common for nameplates, tags, and promotional items because it produces crisp, white markings against vibrant backgrounds.

Laser engraving on aluminum is permanent, corrosion-resistant, and ideal for industrial labeling, awards, signage, and custom promotional products.

Acrylic

Acrylic is one of the most laser-friendly materials, making it a favorite for signage, awards, and decorative pieces.

There are two main types: cast acrylic and extruded acrylic. Cast acrylic engraves with a frosted, white appearance and offers a clean, high-contrast finish—perfect for detailed graphics and text.

Extruded acrylic, on the other hand, tends to melt rather than engrave cleanly, often resulting in less desirable results.

When engraved properly, acrylic produces smooth edges and polished surfaces, especially when cut with a CO₂ laser.

It’s ideal for edge-lit signs, trophies, plaques, and custom displays. Always ensure you’re working with cast acrylic for the best engraving results.

File & Design Preparation for Laser Engraving

Proper file setup is critical to achieving a clean, consistent engraving.

Best practices:

-

Use vector files (.SVG, .AI, .EPS) for sharp lines

-

Convert text to outlines

-

Maintain high contrast in designs

-

Avoid using thin lines on rougher materials like leather or wood

For photo engravings, use high-resolution images converted to grayscale, with dithering or halftone effects applied like the image to the right.

Branding with Laser Engraving

Businesses use laser engraving as a tool to elevate their brand. It allows for subtle, high-quality customization on promotional items, awards, and customer gifts.

Use cases:

- Branded coasters or pens

- Custom plaques or awards

- Leather accessories with your logo

- Engraved name badges

- Custom Tumblers

Laser engraving provides a sleek, long-lasting alternative to stickers or ink printing, with a more premium appearance.

Engraving Software Tools

Behind every great engraving is a well-prepared design file—and that requires reliable software. Whether you’re a beginner or a professional, using the right tools can greatly improve efficiency and output quality.

Popular software options:

- LightBurn – One of the most widely used programs, offering layout, editing, and laser control in one. Compatible with many laser systems.

- Adobe Illustrator / CorelDRAW – While not engraving-specific, these are ideal for creating high-quality vector designs before importing into laser software.

Features to look for:

- Support for vector and raster engraving

- Material-specific presets

- Real-time preview and simulation

- Integration with different machine types

Common Mistakes to Avoid

While laser engraving is relatively easy to learn, there are some common mistakes that can lead to poor results or even material damage.

Avoid these pitfalls:

- Using low-resolution or pixelated graphics

- Skipping material testing

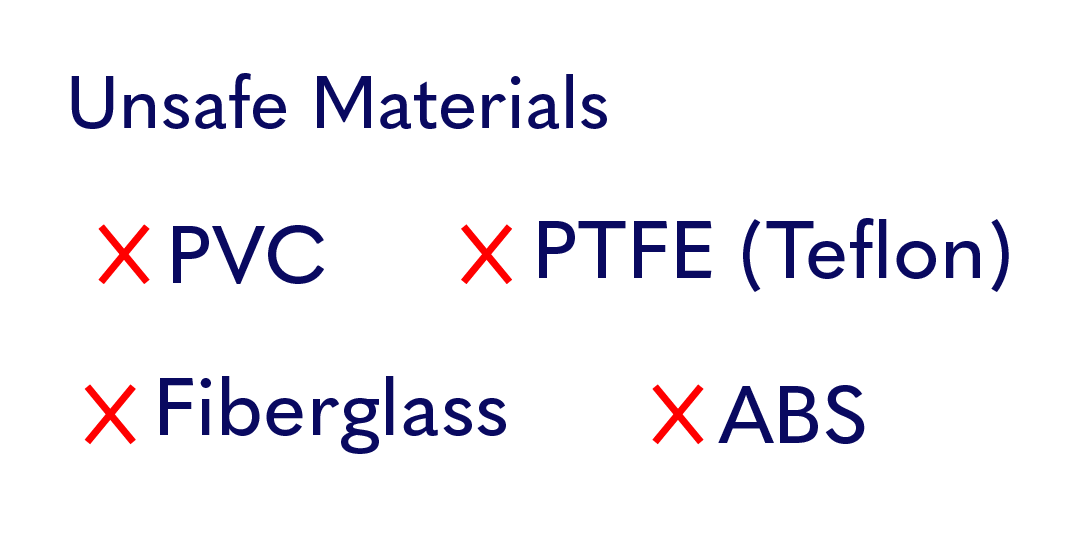

- Engraving PVC or other unsafe materials

- Using incorrect laser settings (e.g., too much power)

- Overcomplicating your design with unnecessary details

Creative Ideas For Your Next Laser Engraving Project

Laser engraving isn’t limited to large-scale production or business uses.

It’s also a fantastic tool for creative makers and gift-givers.

Popular DIY Ideas:

- Custom luggage tags

- Pet Id Tags

- Wedding signage

- Personalized phone stands

- Laser-engraved earrings or ornaments

Small-business product ideas:

- Custom bottle openers

- Keychains with quotes or names

Laser Engraved Name Tags

These laser engraved plastic are the best you will find. With a reinforced plastic they are built to last.

Frequently Asked Questions

Does the engraving fade over time?

No. Since laser engraving removes material, it creates a permanent mark.

Is it possible to engrave one-off items?

Yes. We offer both individual and bulk orders. Click Here to Inquire about custom engravings.

What if I don't have a design file?

No problem! Let us know what your thinking and we can help you out.